Density After Crushing Rock Machine

Powder Mass of Coal After Impact Crushing: A New Fractal

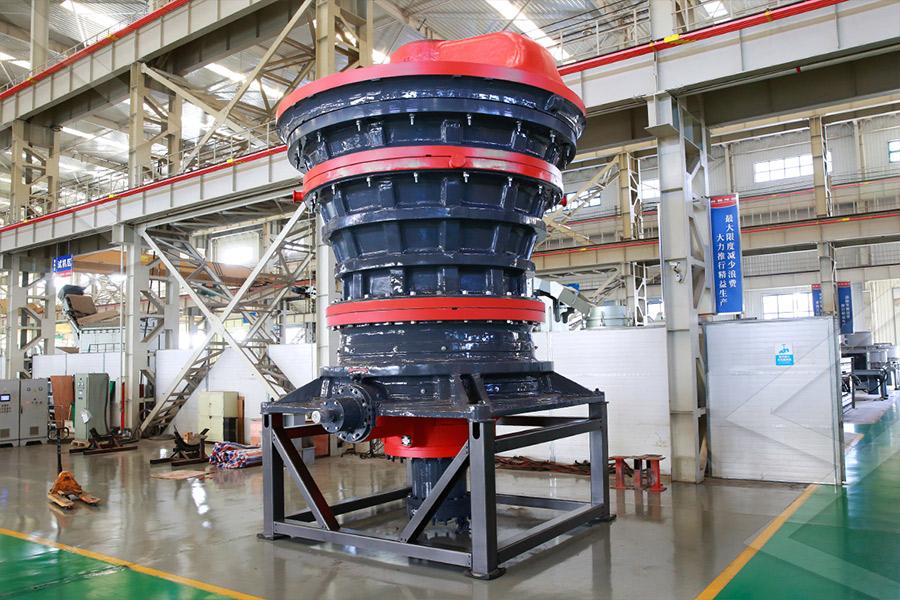

2020年6月17日 In this study, the fractal particlesizedistribution theory was used to calculate the surface areas of coal particles after impact crushing Combining the surface area with the energy input, a new index, fs, that can characterize the surface energy consumption was established2020年6月17日 In this study, the fractal particlesizedistribution theory was used to calculate the surface areas of coal particles after impact crushing Combining the surface area with the Powder Mass of Coal After Impact Crushing: A New Fractal 2021年1月22日 Inadequate unit consumption of explosive and stemming height, faulty drilling, unreasonable borehole density coefficient due to poor previous blast, mismatched explosive Rock Fragmentation Size Distribution Prediction and Blasting Parameter 2023年12月1日 In this study, a customoptimized quadratic RSM model was used to establish the correlation between the crushing performances (throughput, power density and crushing Crushing characteristics and performance evaluation of iron

.jpg)

Reduction of Fragment Size from Mining to Mineral

2022年10月4日 The main factors influencing rock fragmentation are represented by three groups of parameters: (i) explosive (including its density, VOD, and explosion energy) and initiator 2020年12月1日 DEM models including breakage are capable of simulating industrial scale crushers Compression and impact crushers can be investigated in detail using these models Advanced comminution modelling: Part 1 – Crushers☆2021年6月24日 crushing process We are the world’s leading supplier of both unit machines and complete aggregates processing systems Comprehensive process solutions Your system Crushing and Screening Handbook AusIMMConsidering the double fractal characteristics of SSRM, this study revealed the relationship between the fractal dimension and the crushing index and dry density of SSRM The results have significant implications for selecting filling material Fractal Analysis on the Crushing Characteristics

.jpg)

SANDVIK ROCK PROCESSING 911 Metallurgist

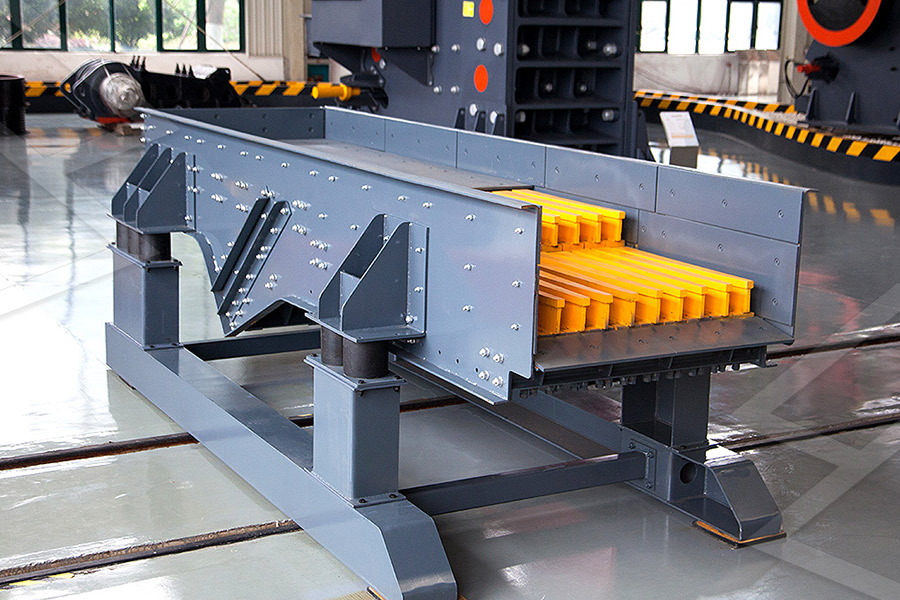

2024年7月26日 Screening ahead of a crusher avoids packing Less wear in the crusher Higher total capacity The product is controlled by the screening cloth and the setting of the crusher 2024年7月11日 In contrast to substantial particle quantity crushing, continuous crushing, and other crushing methods, the particle size distribution of subparticles generated through impact The Crushing Distribution Morphology of a Single Particle 2023年1月8日 It was also observed that the flakiness and shape indexes decreased after crushing, both in the feed with the original geometric composition of the grains and those with flaky and nonflaky particles(PDF) Influence of Basalt Aggregate Crushing Technology on 2023年10月27日 The first step is the rough crushing production of dolomite In this stage, the primary crushing equipment is a jaw crusher Large pieces of dolomite are processed by blasting or excavated for mining and then sent to Dolomite Sand Making Plant And Grinding

.jpg)

Crushed Rock Types Of Pulverizing Machine

Crushed Rock Vertical Shaft Impactor Crusher; the type of crusher is a lot small rock crusher machine for sale rock pulverizer manufacturers; Quartz Stone Pulverizing System, Ball Mill for Ore Crushing2021年1月22日 Rock fragmentation size distribution is often used as an important index to account for the blasting effect because it directly affects the subsequent loading, transportation, and secondary crushing Due to the mismatching of explosive and rock wave impedance, high boulder yield often occurs which affects the blasting effect In this study, methods of Rock Fragmentation Size Distribution Prediction and Blasting Parameter 2023年2月24日 Crushed stone machines play a critical role in the construction industry by crushing large rocks into smaller, more manageable pieces that can be used in a variety of building projects In this comprehensive guide, we explore the different types of crushed stone machines, their components, and how to operate them safely and efficiently We also highlight Crushed Stone Machines: The Key to HighQuality Building 2022年10月9日 The uniaxial compressive strength of rock is one of the most significant parameters required for analysis of rock mass, its characterization, and design of foundations Direct determination of the uniaxial compressive strength of rock is timeconsuming, expensive, and requires destructive laboratory or field testing Therefore, indirect methods based on Prediction of Uniaxial Compressive Strength of Rock Using Machine

.jpg)

Enhancing rock fragmentation assessment in mine blasting

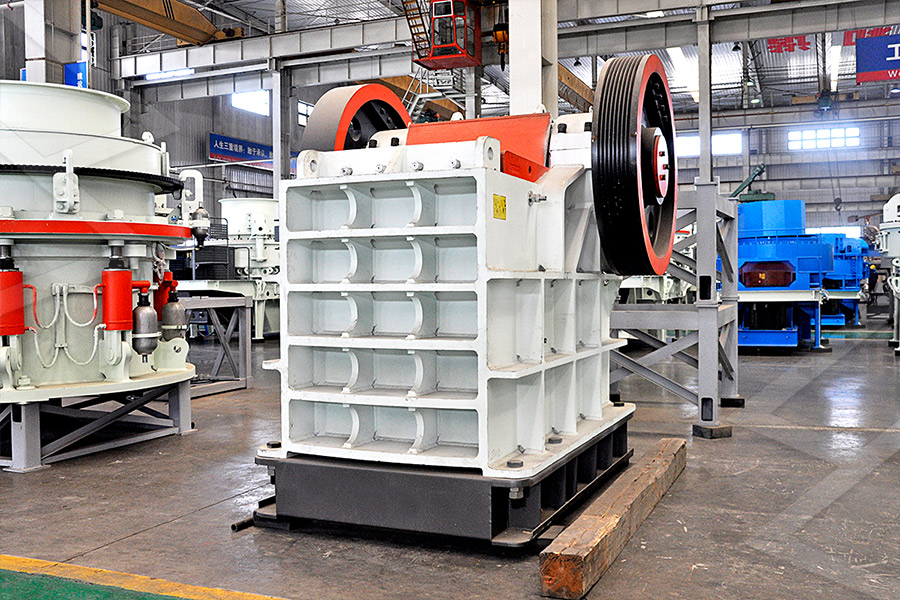

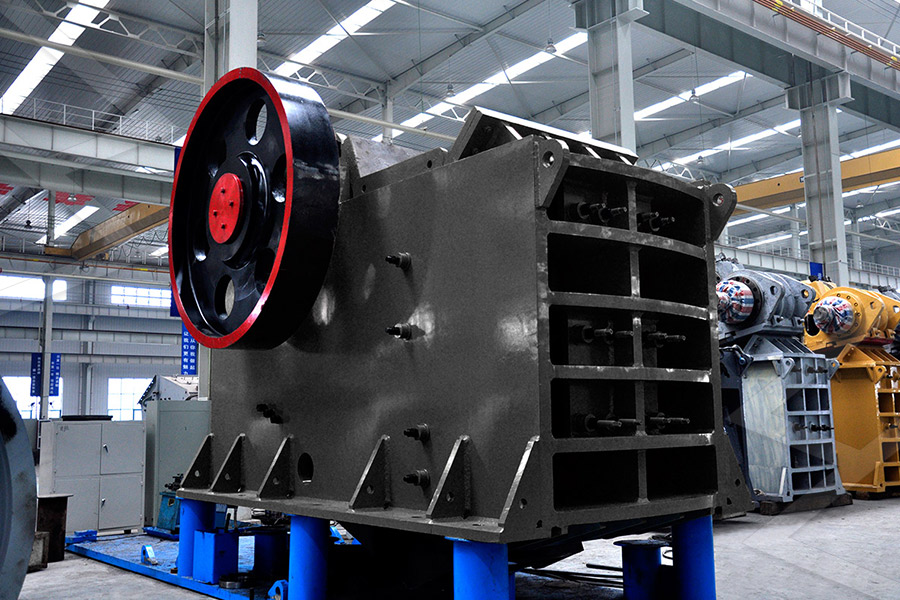

2024年4月25日 The optimization of blasting operations greatly benefits from the prediction of rock fragmentation The main factors that affect fragmentation are rock mass characteristics, blast geometry, and explosive properties This paper is a step towards the implementation of machine learning and deep learning algorithms for predicting the extent of fragmentation (in 2024年1月11日 The crushed material enters a belt conveyor and goes to a fine jaw crusher(impact crusher or hammer crusher) for further crushing After crushing, the material enters a vibrating screen to separate two types of stones The output material meets the feeding particle size of the sandmaking machine and enters the sandmaking machineLimestone Crushing And SandMaking Plant Eastman Rock 1 天前 Stages of Rock Crushing: Crushing Stations These types of machines break apart material by the impacting forces of certain wear parts known as blow bars and impact plates or toggles Some operations also use impactstyle crushers after they have already used a different type of rock crusher that produces a more elongated stone This helps Types of Rock Crushers Quarry Crushing Equipment Kemper2021年6月24日 machines for soft and mediumhard materials High reduction ratios Can eliminate need for a tertiary crushing stage Spare and wear parts – genuine parts always close to you, no matter where you are located worldwide Vertical shaft impactors – helps shape the rock to highquality aggregates Rock on rock crushingCrushing and Screening Handbook AusIMM

The Ultimate Guide to Rock Crushers Mellott

2024年5月30日 So, let’s embark on this journey to understand rock crushing equipment better Understanding Rock Crushing Equipment Rock crushing equipment is a broad term It refers to any machine that reduces large rocks 2022年1月18日 In order to investigate the compaction and recrushing characteristics of crushed coal gangue with different gradation, the compaction fractal test was carried out for crushed coal gangue with different Talbol power index n The compaction deformation parameters such as displacement, stressstrain were analyzed according to the test results And according to the Study on the distribution pattern of particle recrushing in 2024年10月6日 Stone Crusher, also known as rock crusher, is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust It utilizes a highpressure force to crush the rocks and is widely used in various industries such as Stone Crusher Rock Crushing Machine2023年12月1日 A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be moreSIZE REDUCTION BY CRUSHING METHODS By

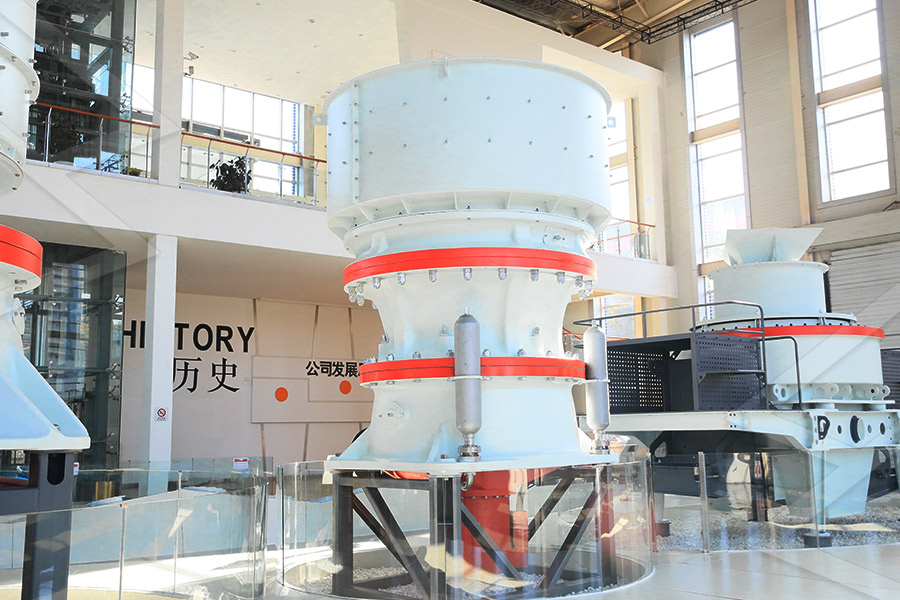

Evaluation of size reduction process for rock aggregates in

2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher Based on several mineralogical, physico 2023年2月23日 Yes, the rock crusher machine is userfriendly, with simple controls that make it easy to operate How does the rock crusher machine help to reduce mining costs? The rock crusher machine reduces mining costs by enabling mining companies to crush rocks onsite, eliminating the need to transport them to a crushing facility Conclusion:The Rock Crusher Machine: A Revolutionary Equipment for Crushing 2024年6月28日 Rock crushers, specially designed machines, play a vital role in industries like mining, construction, and recyclingThey are responsible for breaking down large rocks into smaller, more manageable pieces for different applications There are two main groups of rock crushers: compressive crushers, which include primary crushers used in the first stage of the Crusher Rock: Exploring the Types of Rock CrushersSoilrock mixtures (SRM) are extensively utilized as filling materials in engineering slopes and roadbeds A comprehensive understanding of the crushing characteristics of SRM during compaction is essential for precisely controlling its mechanical properties, particularly when dealing with SRM comprising soft rock blocks This study conducted heavy compaction and Fractal Analysis on the Crushing Characteristics of SoilSoft Rock

.jpg)

(PDF) Design and Construction of Rock Crushing Machine

PDF On Aug 7, 2018, Ocheri c published Design and Construction of Rock Crushing Machine from Locally Sourced Materials for Indigenous Use Find, read and cite all the research you need on Willpactors thrive in highcapacity applications such as crushing large runofmine rock Machines are available in different sizes to accommodate 44” to 72” rock External product size adjustment and solid impact block adjustment are just some of the features of these rock crushing machinesRock Crushers Pulverizers Williams Crusher2024年7月24日 The evolution of rock crushing machines Rock crushing technology has seen remarkable advancements since its inception Early devices were rudimentary, relying on basic mechanical principles to break down rocks Over time, technological innovations have led to the development of sophisticated machines capable of handling a variety of materials with Rock crushing machines: transforming rocks into valuable2016年7月1日 Equation (7) is the fractal energy consumption density model of rock crushing, which can be directly determined by the rock fracture surface energy and fragmentsize distribution 3 a rock cutting machine and polishing machine are adopted to grind and polish the two end faces of the samples In addition, before the SHPB tests, uniaxial Theoretical analysis and experimental research on the energy

.jpg)

Small Portable Rock Crushing Machinery Senya

Then, on June 15, 1858, Blake was granted US patent No 20,542 for a “machine for crushing stone” This machine was eventually used all over the country to build roads while serving the main purpose of replacing manual and costly 2007年1月31日 In order to explore the influence of AMF contents in machinemade sand on volume stability of concrete in plastic stage, the single factor method was used to control the AMF content by mass Aggregate production: Fines generation during rock crushing2016年10月23日 Aberdeen Diorite, RF 841—This is a rock of high crushingstrength but not tough, and of relatively low resistance to attrition The rock is dominantly composed of plagioclase felspars and green fibrous hornblende, tending towards actinolite The grainsize of these minerals is coarse There is a minor amount of orthoclase and very little Rock Abrasion Crushers 911Metallurgist2023年4月27日 Ballast stone crushing machine, or ballast crusher, breaks rock and stone into small pieces for use in railways, roads, and concrete Ballast stone crushing machine, or ballast crusher, breaks rock and stone into small pieces for use in railways, roads, and concrete The density of the stone is 2g per cubic centimeter Its specifications Ballast Stone Crushing Machine Price in Kenya Fote

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022年1月23日 Bulk Density of the blasted or excavated ore most competent, and abrasive feed materials that are typical in hardrock mining like some Diasporic bauxite Fig 31 a Compression—type crushers b Compression—type crushers Then if multiple machines or crushing stages were required for a project, the crushing station was still of an 2004年2月27日 Quality estimation of rock aggregate raw materials is often performed with mechanical tests on aggregates crushed with laboratory crushers However, standardised mechanical tests are intended for testing products, not raw materials Different laboratory crushers produce aggregates with varying shape properties [flakiness index (FI), shape index and An evaluation of the procedure and results of laboratory crushing 2024年7月19日 Sand Making Machine / Vertical Shaft Impact Crusher Get a Quote Crucial equipment after crushing: rock screeners Get a Quote Following rock crushers, rock screeners become crucial as they precisely classify crushed stone into large, medium, small stones, and stone powder, meeting specific granularity requirements for various engineering How to Crush Stones: A Comprehensive Guide Fote Porosity and Density (Buoyancy Method – ISRM 2007) £ 3000: Porosity and Density (Caliper Method – ISRM 2007) Preparation needed if not perfectly shaped: £ 3000: Void Index (Quick absorption technique – ISRM 2007) £ 3000: Sample preparation (if required) £ 3000 / sampleRock Testing Geolabs

Comparative Study on Mechanical Properties and Crashing

2023年5月26日 As the mileage of long tunnels and the number of underground engineering projects continue to increase, the issue of rock mass stability after fire and explosion becomes increasingly prominent Therefore, studying high strain rates mechanical properties of rocks under different heat treatment methods is of great significance to the design of geological Density; Milling media with higher density usually have better milling efficiency and can lead to smaller final particle size of the material to be ground The media should have higher specific gravity than the material to be milled Hardness; Grinding Mill Eastman Rock Crusher2024年3月27日 The next big step is blasting, where they use explosives to break up the kimberlite, making it possible to pull out the diamondrich ore After the explosion, the broken ore is gathered from the bottom of the pit They The Ultimate Guide to Diamond Processing 2024年10月25日 Limestone application The compact limestone has a compressive strength of 20~120MPa and a density of 2000~2600 kg/m3 When the clay impurities in the limestone exceed 3% to 4%, the frost resistance and water resistance are remarkably loweredLimestone Crushing Plant Layout and Price JXSC Machine

.jpg)

Introduction to Crushing 911 Metallurgist

2024年9月24日 The bulk density depends on the solid density of the rock and the size distribution of the feed The solid density of an iron ore may have double the density of granite, which means that the ton per hour is doubled If the solid density is constant the bulkdoubled If the solid density is constant, the bulk3 天之前 Impacttype Limestone Crushing Machine – for Secondary or Tertiary Crushing The output is calculated based on mediumhard materials and a bulk density of 16t/m3 2 The power is calculated based on mediumhard materials and an altitude below 1000 meters VSI Crushers – for Fine Crushing VSI crushers utilize the principle of rock Limestone Crusher Machine: Boost Quarrying Mining 6 天之前 • Density • Particle size, mineral composition, shape of grains, texture, crystallinity, stratification, lamination influences the strength 13 excavation machine in Soft to Medium rock formations like gypsum or salt Drum Cutters are a very good solution for scaling or profilingHydraulic attachment tools in underground rock 2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process +86 ne 19F, Suite B, Global Trade Mansion The Complete Guide to Primary Crushing, Secondary Crushing

.jpg)

How To Crush Rock 6 Ways For You Aimix Group

1 天前 The process of rock crushing requires manpower to operate and manage the equipment, labor costs include wages, training and management costs Raw material costs The rock crushing process may require the use of some raw materials and chemicals, such as lubricants, lubricants, etc, and these raw material costs need to be included in the total costIn a tough environment, you need robust equipment that won’t let you down The Double Roller Crusher is a heavyduty machine designed to withstand the rigours of the mining industry With high capacities and minimum downtime, this rolling crusher is ideal for both soft and mediumhard rock crushing applicationsDouble Roll Crusher DRC FLSmidth